now:主页 > Enterprise Dynamic > Company News >

time:2024-11-27 16:55 次

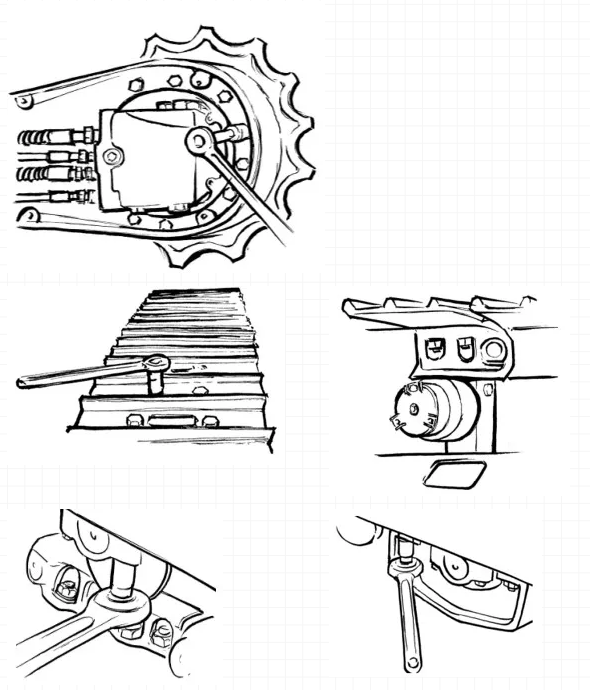

In the realm of mechanical engineering and manufacturing, guide wheels play a crucial role in various applications, from conveyor systems to precision machinery. These components are designed to provide smooth and controlled movement, ensuring that machines operate efficiently and with minimal wear and tear. This article delves into the significance, design, materials, and applications of guide wheels in mechanical manufacturing.

Significance of Guide Wheels

Guide wheels are essential for maintaining the alignment and stability of moving parts in machinery. They help reduce friction, prevent misalignment, and ensure consistent performance. By providing a smooth surface for contact, guide wheels minimize the risk of damage to both the wheel itself and the surfaces it interacts with. This is particularly important in high-speed or heavy-duty applications where precise control is critical.

Design Considerations

The design of guide wheels varies depending on their specific application. Key factors include:

1. Material Selection: The choice of material depends on the operating environment and the loads involved. Common materials include steel, aluminum, plastic, and composite materials. Steel is often used for its strength and durability, while plastics offer lightweight and low-friction properties.

2. Bearing Type: Guide wheels can be equipped with different types of bearings, such as ball bearings, roller bearings, or plain bearings. Ball bearings are ideal for high-speed applications, while roller bearings handle heavier loads more effectively.

3. Shape and Size: The shape and size of the wheel must match the requirements of the system. For example, V-shaped wheels are commonly used in conveyor systems to maintain alignment, while flat wheels are suitable for linear guides.

4. Mounting Options: Guide wheels need to be securely mounted to the machine frame. Various mounting options, such as bolt-on, shaft-mounted, or flange-mounted designs, are available to suit different installation needs.

Materials

Steel: Known for its strength and durability, steel is widely used in industrial applications where robustness is paramount.

Aluminum: Lightweight and corrosion-resistant, aluminum is preferred in applications where weight reduction is necessary.

Plastic: Plastics like nylon and polyurethane offer low friction and noise reduction, making them suitable for precision instruments and consumer goods.

Composite Materials: Composites combine the advantages of multiple materials, offering enhanced performance in terms of strength, weight, and resistance to environmental factors.

Applications

1. Conveyor Systems: Guide wheels are integral to conveyor systems, ensuring that products move smoothly along the production line without deviation.

2. Automation Equipment: In automated machinery, guide wheels help maintain the accuracy and repeatability of robotic arms and other moving components.

3. Material Handling: Guide wheels are used in material handling equipment, such as forklifts and pallet jacks, to facilitate easy and safe movement of heavy loads.

4. Precision Machinery: In precision machinery, such as CNC machines and medical devices, guide wheels ensure that movements are accurate and reliable.

5. Automotive Industry: Guide wheels are employed in automotive assembly lines and testing equipment to ensure consistent and efficient operation.

Maintenance and Care

To ensure optimal performance and longevity, regular maintenance of guide wheels is essential. This includes:

Lubrication: Proper lubrication reduces friction and wear, extending the life of the wheel.

Inspection: Regular inspection helps identify signs of wear or damage early, allowing for timely replacement.

Cleaning: Keeping the wheels clean prevents contamination and ensures smooth operation.

Conclusion

Guide wheels are indispensable components in mechanical manufacturing, contributing to the efficiency, reliability, and safety of various systems. By understanding their design, materials, and applications, engineers and manufacturers can select the most appropriate guide wheels for their specific needs, thereby enhancing the overall performance of their machinery. Whether in conveyor systems, automation equipment, or precision machinery, the right guide wheels make all the difference in achieving operational excellence.